High-Temperature Furnaces with MoSi2 Heating Elements up to 1800 °C Model LHT

ยี่ห้อ Nabertherm

ประเทศ เยอรมัน

- Description

- Tmax 1600 °C, 1750 °C, or 1800 °C

- High-quality molybdenum disilicide heating elements

- Furnace chamber lined with first-class, long-life fiber material, unclassified

- Housing made of sheets of textured stainless steel

- Dual shell housing with additional fan cooling for low surface temperature

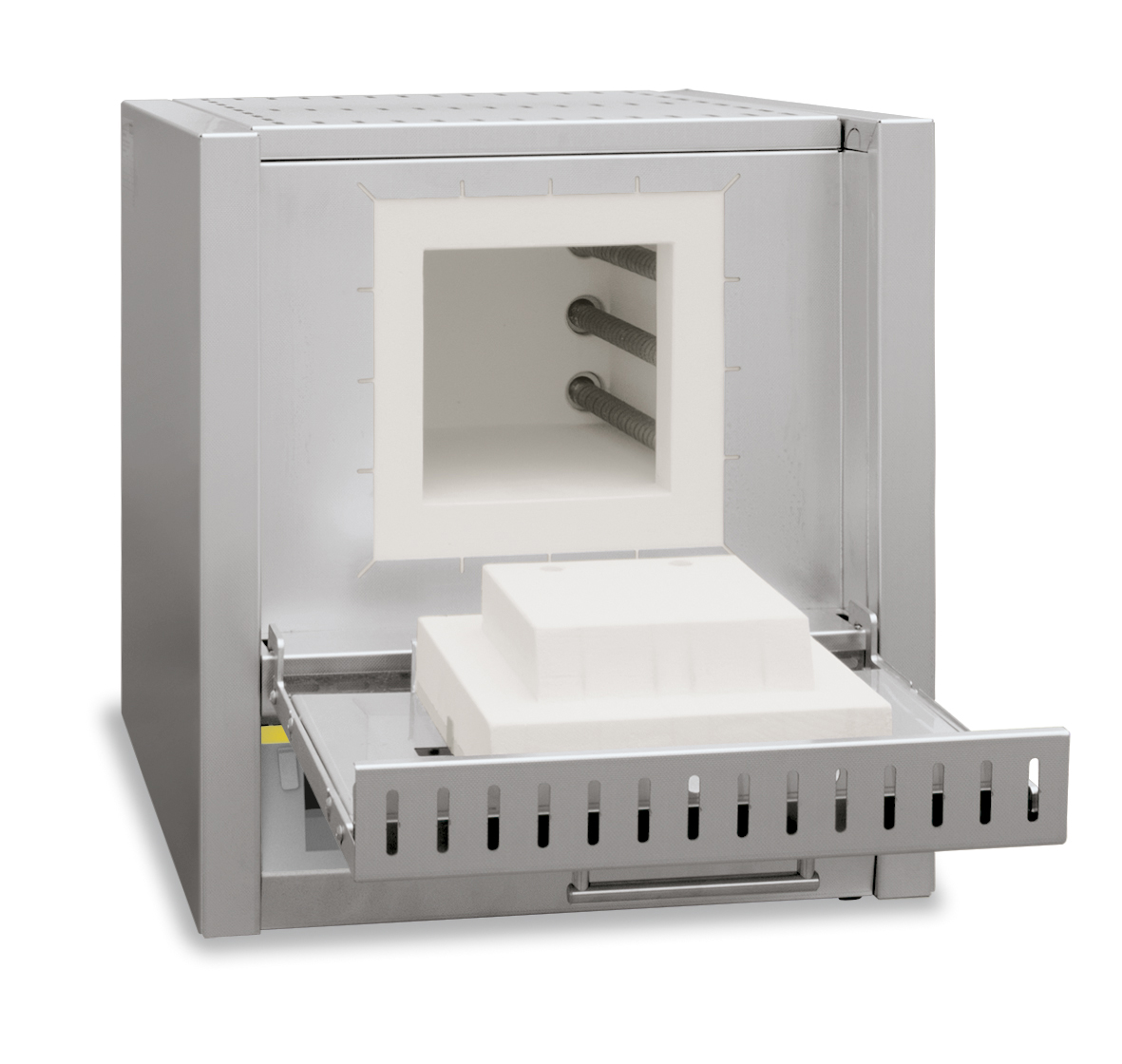

- Compact design with lift door, opening upwards

- Adjustable air inlet

- Exhaust air opening in the roof

- Type B thermocouple

- Switchgear with steady control of the heating elements

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Over-temperature limiter with adjustable cutout temperature for thermal protection class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace and load

- Square saggar for charging of up to three layers

- Protective gas connection to purge with non-flammable protective or reaction gases

- Manual or automatic gas supply system

- Process control and documentation via VCD software package for monitoring, documentation and control

- Tmax 1700 °C

- High-quality molybdenum disilicide heating elements

- Furnace chamber lined with first-class, long-life fiber material, unclassified

- Outstanding temperature uniformity due to all-round furnace chamber heating

- Furnace chamber with a volume of 2 or 16 liters, table with large floor space

- Precise, electric belt drive with push button operation

- Housing made of sheets of textured stainless steel

- Exhaust air vent in the roof

- Type S thermocouple

- Switchgear with thyristor

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Over-temperature limiter with adjustable cutout temperature for thermal protection class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace and load

- Saggar for charging of up to three layers

- Protective gas connection to purge with non-flammable protective or reaction gases

- Manual or automatic gas supply system

- Adjustable air inlet through the floor

- Process control and documentation via VCD software package for monitoring, documentation and control

Designed as tabletop models, these compact high-temperature furnaces have a variety of advantages. The first-class workmanship using high-quality materials, combined with ease of operation, make these furnaces all-rounders in research and the laboratory. These high-temperature furnaces are also perfectly suited for the sintering of technical ceramics, such as zirconium oxide dental bridges.

Additional equipment

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions in mm | Connected | Electrical | Weight | Minutes | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H3 | load kW | connection* | in kg | to Tmax2 | |

| LHT 02/16 | 1600 | 90 | 150 | 150 | 2 | 470 | 630 | 760+260 | 3.0 | 1-phase | 75 | 30 |

| LHT 04/16 | 1600 | 150 | 150 | 150 | 4 | 470 | 630 | 760+260 | 5.2 | 3-phase1 | 85 | 25 |

| LHT 08/16 | 1600 | 150 | 300 | 150 | 8 | 470 | 810 | 760+260 | 8.0 | 3-phase1 | 100 | 25 |

| LHT 01/17 D | 1650 | 110 | 120 | 120 | 1 | 385 | 425 | 525+195 | 3.5 | 1-phase | 28 | 10 |

| LHT 03/17 D | 1650 | 135 | 155 | 200 | 4 | 470 | 630 | 760+260 | 3.0 | 1-phase | 75 | 60 |

| LHT 02/17 | 1750 | 90 | 150 | 150 | 2 | 470 | 630 | 760+260 | 3.0 | 1-phase | 75 | 60 |

| LHT 04/17 | 1750 | 150 | 150 | 150 | 4 | 470 | 630 | 760+260 | 5.2 | 3-phase1 | 85 | 40 |

| LHT 08/17 | 1750 | 150 | 300 | 150 | 8 | 470 | 810 | 760+260 | 8.0 | 3-phase1 | 100 | 40 |

| LHT 02/18 | 1800 | 90 | 150 | 150 | 2 | 470 | 630 | 760+260 | 3.6 | 1-phase | 75 | 75 |

| LHT 04/18 | 1800 | 150 | 150 | 150 | 4 | 470 | 630 | 760+260 | 5.2 | 3-phase1 | 85 | 60 |

| LHT 08/18 | 1800 | 150 | 300 | 150 | 8 | 470 | 810 | 760+260 | 9.0 | 3-phase1 | 100 | 60 |

High-Temperature Furnaces Lift-Bottom up to 1700 °C

The electrically driven lift-bottom considerably allows for proper charging of the high-temperature furnaces LHT/LB. The heating all around the cylindrical furnace chamber provides for an opitimal temperature uniformity. For high-temperature furnace LHT 02/17 LB the charge can be placed in charge saggars made of technical ceramics. Up to three charge saggars can be stacked on top of each other resulting in a high productivity. Due to its volume the high-temperature furnace LHT 16/17 LB can also be used for applications in production.

Additional equipment

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions in mm | Connected | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|

| °C | Ø | h | in l | W | D | H | load kW | connection* | in kg | |

| LHT 02/17 LB | 1700 | Ø 120 | 130 | 2 | 540 | 610 | 740 | 2.9 | 1-phase | 85 |

| LHT 16/17 LB | 1700 | Ø 260 | 260 | 16 | 650 | 1250 | 1980 | 12.0 | 3-phase | 410 |