Fistreem Cyclon Ultrapure Water Stills

ยี่ห้อ FISTREEM

ประเทศ สหราชอาณาจักร

- Description

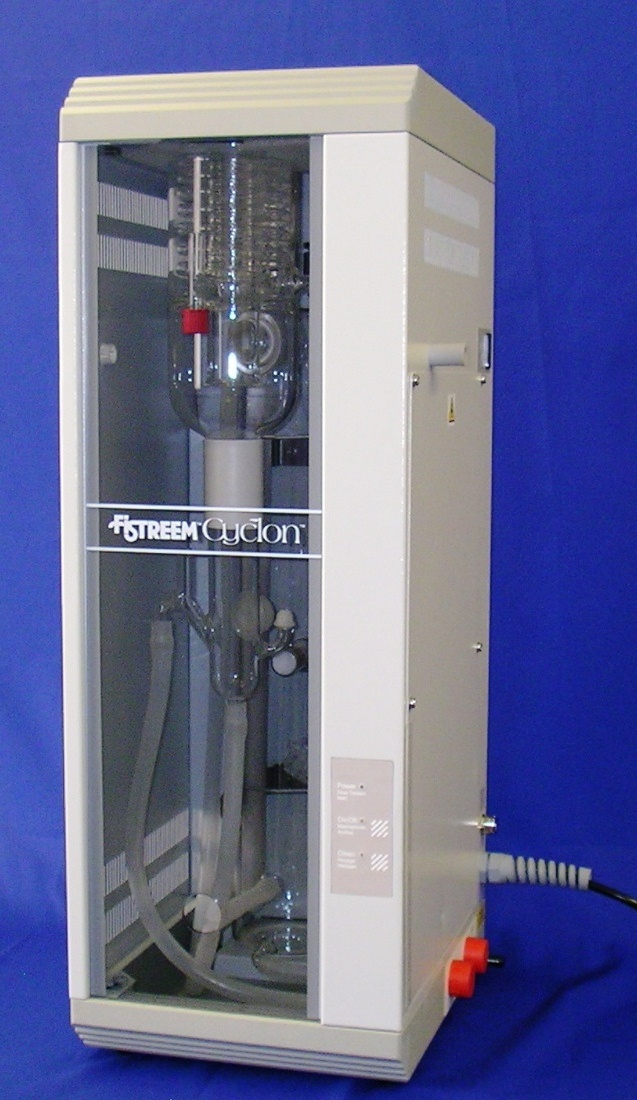

Fistreem Cyclon Ultrapure Water Stills

Fistreem have been the leaders in water still innovation for many years with a reputation for design, quality and reliability.

Distillation is recognised as offering considerable advantages being fail safe in concept and consistently free from impurities including inorganics, organics, micro-organisms and pyrogens.

Fistreem Ultrapure Water stills improve on this concept through a unique patented vapour trap which creates a 'cyclonic' effect eliminating all vapour borne droplets, ensuring that there is no carry over of impurities in the distillate. The resultant pyrogen free water is therefore at the highest purity - at all times.

Cyclon Stills embody modern electronics and include dual safety systems, auto reservoir control, easy cleaning, matching storage reservoir and optional pre-Deioniser

Outputs of 4 and 8 litre/hour single distillers and 4 litre/hour double (Bi) distiller are offered. They are factory supplied for tap feed use. A pretreated feed option is supplied with the still which allows a variety of treated feed sources to be fed in a controlled way for further polishing by distillation.

The quality of the pyrogen free distillate make these stills highly suitable for life science applications.

Cyclon: An Integrated Water Purification System

The Cyclon is available in 4 or 8 l.hr -¹ single distilled or 4 l.hr -¹ double distilled formats and as a complete water purification system with matching pre-deioniser and distillate reservoir. To eliminate the need for routine cleaning in hard water areas, the Stills are also able to be adapted to accept pre-treated water.

All systems can be wall or bench mounted while tap feed models can easily be upgraded to use pre-treated water.

Purity

The patented 'cyclonic' vapour trap eliminates all carry over while the advanced borosilicate glassware design removes the risk of foaming and improves purity levels. The distillate leaves the condenser at the optimum temperature to guarantee product quality. Additionally quartz sheathed heating elements ensure distillate purity is not compromised.

Bi-Distiller Model

For increased purity the double ( Bi- ) distiller is particularly welcome in life science applications where the highest grade distillate is required. Comprising two identical sets of glassware and heaters the first distillation is fed to the second boiler for further distillation thus eliminating any possible carry over of impurities. The 4BD model produces 4 lt per hour double distilled water.

Safety in Operation

The thermistor protects the still against interruptions in the water supply by controlling heater operation. Additional protection is provided by a thermal cut-out fuse to prevent overheating.

Operator protection is assured through totally enclosed glassware and a built-in spillage tray.

Reliability and Ease of Use

Combined with the microprocessor, the thermistor sensor provides precise control of the still and simplifies operation and cleaning procedures.

A vertical boiler configuration minimises stress on the durable silica sheathed heating elements. Along with an auto-drain function this design also helps to reduce the build-up of scale.

The Cyclon is supplied with an electronic float switch which will shut off the still automatically when the storage reservoir is full enabling safe, unattended operation.

Economy

The flow of cooling water is automatically controlled to minimise water usage.

Cyclon Pre-treated Feed Option

Feeding the still with pre-treated water can eliminate the need for descaling of the still's boiler in hard tap water areas.

All Cyclon Stills are supplied with accessories which enable the user to adapt from tap feed to treated feed supply. In this configuration, for economy, the treated water for the boiler and the tap water for the condenser are separated.

The stills can be fed from the matching Cyclon Deioniser which is specially designed to provide quality pre-treated water. The deioniser is electronically controlled by the still's microprocessor to ensure optimum use is made of the deioniser's ion exchange capacity.

Alternatively, the Cyclon can be used with pre-treated water from the user's own source. Suitable quality water includes reverse osmosis, deionised or purified water from a central piped supply.

Cleaning

Descaling is simplified by an automated cleaning facility requiring no dismantling of glassware. The highly efficient process requires little operator time. The microprocessor and thermistor controlled operation incorporates a dual flush program to ensure the Still is ready to return to normal service on completion.

Cyclon Deioniser

The Cyclon pre-Deioniser features a simple to read conductivity meter which indicates resin exhaustion and a separate outlet tap allowing users to draw off deionised water at any time. The Still’s microprocessor controls the operation of the Deioniser to ensure the optimum use of purified water.

The deioniser will typically provide up to 700 litres of purified water on 200ppm tds water. On exhaustion the resin can either be regenerated or replaced by new resin. Replacement resin packs are offered to users should a local regeneration service be unavailable.

Cyclon Reservoir Tank

The 30 litre matching Cyclon reservoir tank incorporates a fast flow tap and a sight tube showing the contents of the reservoir. Distillate access ports are fitted on both sides allowing the reservoir to be sited either side of the still.

To ensure the highest purity levels are maintained, the reservoir features a polyethylene liner, vent filter and a cleaning access port. The electronic float switch shuts off the still on a full reservoir.

All models are wall or bench mountable and are supplied with all necessary connection hoses.

Specifications

| Model | WSC004 | WSC044 | WSC008 |

| Output Capacity | 4 litres. hr- Single distilled | 4 litres. hr- Double distilled | 8 litres. hr- Single distilled |

| Pyrogen Free | Yes | Yes | Yes |

| pH | 5.6 -6.0 | 5.6 -6.0 | 5.6 -6.0 |

| Conductivity | 1µS. cm- | <1µS. cm- | 1µS. cm- |

| Power Rating | 3kW | 6kW | 6kW |

| Tap Water Pressure (min-max)* | 70-560 kPa 10-80 lbf.in- | 70-560 kPa 10-80 lbf.in- | 70-560 kPa 10-80 lbf.in- |

| Tap Water Flow (min) | 1 litre. min- | 2 litres. min- | 2 litres. min- |

| Dimensions (HxWxD)mm | 750 x 300 x 380 | 750 x 490 x 380 | 750 x 490 x 380 |

| Weight | 25kg | 29kg | 29kg |

Ordering Information

| Catalogue No | Output | Power | Dimensions WxDxH (mm) |

| WSC004.MH3.4 | 4 L/hr Single | 220V 3kW | 300 x 380 x 750 |

| WSC004.MH3.7 | 4 L/hr Single | 240V 3kW | 300 x 380 x 750 |

| WSC008.MH3.4 | 8 L/hr Single | 220V 6kW | 490 x 380 x 750 |

| WSC008.MH3.7 | 8 L/hr Single | 240V 6kW | 490 x 380 x 750 |

| WSC044.MH3.4 | 4 L/hr Double (Bi) | 220V 6kW | 490 x 380 x 750 |

| WSC044.MH3.7 | 4 L/hr Double (Bi) | 240V 6kW | 490 x 380 x 750 |

Accessories

| Catalogue No | Description | Capacity | Dimensions WxDxH (mm) |

| WSC900.RTB.9 | Storage Reservoir | 30 litre | 300 x 380 x 750 |

| WSC901.PDC.5 | Cyclon Pre-Deioniser | - | 300 x 380 x 750 |

Replacement Parts

| WSC703.BXJ.9 | Boiler |

|---|---|

| WSC705.CXJ.9 | Condenser |

| WSC707.CLJ.9 | Constant Level Device |

| WSC708.HEJ.4 | Heating Element 220V 1.5kW |

| WSC710.HEJ.7 | Heating Element 240V 1.5kW |